Yuanjiang Brand - is calcined kaolin with advanced equipment, Britain and America after super fine crushing, calcination modification.Product type crystal is false and porous lamellar structure, porosity is about 75%.This kind of porous lamellar structure of kaolin with plasticity, cohesiveness, decentralized, insulation, sinter strength, flame retardant, fire resistance, adsorption, the weathering resistance, stable chemical performance, high light scattering rate, good covering power, etc.Widely used in paper coating, paper packing, plastic, rubber, wire and cable, emulsioni paint, road sign paint, powder coating, and other fields.

One, the main standards and features

|

chemicals |

Kaolinite/calcination |

|

The product status |

White powder |

|

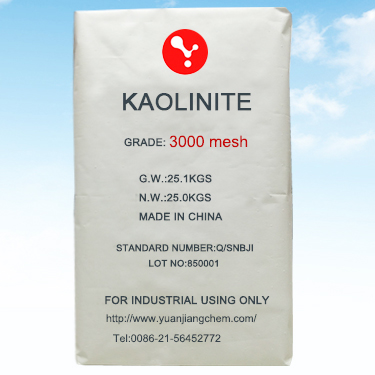

Package is installed |

25 kg woven bag/kraft paper, 1000 kg big bags |

|

Product main features |

Advanced equipment, Britain and America after super fine crushing, calcination modification.Malleable, cohesiveness, dispersion, insulation, sinter strength, flame retardant, fire resistance, adsorption, the weathering resistance, stable chemical performance, high light scattering rate, good covering power, etc. |

|

Range of application |

Used in paper coating, paper packing, plastic, rubber, wire and cable, emulsioni paint, road sign paint, powder coating, and other fields. |

|

Network real-name |

Titanium dioxide barium sulfate manganese carbonate hydroxide |

Second, the quality indicators

|

The serial number |

project |

Single bit |

Physical refers to the |

|

325-800 mesh |

1250-6000 mesh |

|

1 |

whiteness |

% |

90 + 2 |

93 + 2 |

|

2 |

The fineness of 325 mesh sieve residue (according to the practical and decide) |

% |

0.1 or less |

0.05 or less |

|

3 |

The refractive index |

% |

1.55 |

1.65 |

|

4 |

moisture |

% |

0.6 or less |

0.5 or less |

|

5 |

Water slurry PH |

|

6.5 to 7.2 |

6.5 ~ 7.5 |

|

6 |

Oil absorption (according to different fineness) |

% g/100g |

50 + / - 5 |

68 + / - 5 |

|

The fineness of 325 mesh, 400 mesh, 600 mesh, 600 mesh, 1250 mesh, 2000 mesh

The fineness of 3000 mesh, 6000 mesh (according to customer requirements)

|

Three, chemical index

|

SiO2(%) |

Al2O3(%) |

Fe2O3(%) |

TiO2(%) |

CaO(%) |

MgO(%) |

K2O(%) |

Na2O(%) |

MnO(%) |

|

52 + 2 |

45 + 2 |

< 0.4 |

< 1.0 |

< 0.4 |

< 0.2 |

< 0.04 |

< 0.1 |

< 0.005 |

|